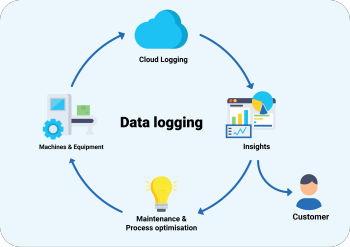

Data Logging refers to collecting and recording data over an extended period. Often using sensors and computers for this task.

Temperature, pressure, humidity, or voltage measurements can all be taken. Furthermore, multi-input loggers exist to monitor multiple variables at once.

How it Works

Data logging's basic purpose is to record information that would otherwise be difficult or impossible to collect manually, such as temperature readings at regular intervals taken automatically by an automated temperature logger instead of someone having to walk around with a thermometer and write them down manually in a notebook. With data logging, that information can then be instantly accessed for analysis or planning purposes by those needing it.

Data logging devices vary depending on their intended application; however, most consist of a sensor, microprocessor board with memory, and output device. A sensor converts electrical measurements into forms that the microprocessor board can easily read before being stored in memory or sent somewhere for download and further processing.

Data loggers come with various inputs, ranging from single-value units to more sophisticated models with multiple parameters monitored simultaneously. Some devices specialize in specific data inputs like temperature, relative humidity, or voltage/current, while others accept mixed signal inputs. Many provide visual displays showing the current value of their sensor(s), while some come equipped with built-in computer interfaces for real-time monitoring via wired or wireless connections.

Data recorded by devices may also trigger alarms, making the data extremely useful in industrial settings where conditions have been breached. An immediate response must be provided - for instance, if a shipping container's temperature falls outside its acceptable parameters, alerting personnel so they can take measures to protect their product inside from being damaged by temperature variances.

Other types of data logging are used to monitor complex IT systems. This could involve anything from individual user actions on software applications to server traffic - data collected can then be used to detect and address potential issues which might otherwise go undetected, improving system performance.

Advantages

Data logging enables businesses to record, observe and assess conditions over extended periods. The resulting information can then be used to monitor processes, correct or enhance them, meet industry or regulatory compliance obligations, and safeguard personnel and customers.

Data Loggers come in all shapes and sizes, from economical single-channel fixed-function devices to more powerful programmable logs that simultaneously monitor multiple inputs. Some have displays for only showing single values; others offer expansion capabilities or special features that make them suitable for specific uses.

Devices used for data logging may be either battery-powered or AC-powered and feature nonvolatile memory for recording even when switched off. Certain loggers are even designed to integrate with specific programming environments for easy integration into an existing system. Depending on their intended application or monitoring site, they may feature USB, radio, or Ethernet connectivity options.

No matter their application, most data loggers offer some form of alarm indication that alerts users to any conditions outside their prescribed range, enabling them to take immediate steps and prevent costly or dangerous scenarios from arising.

Temperature control is especially essential for products like medicines and vaccines that rely on tight temperature management to remain effective or safe to use, like vaccines. According to EU Directive 92/1 and FDA regulations, food must remain within certain temperatures throughout preparation, storage, and transportation processes; similarly, hospital HVAC systems must maintain constant temperatures to protect patients' and visitors' health and well-being.

Data Logging simplifies compliance by offering customized alarms and alerts that simplify compliance management for companies. Configuring devices to notify when readings go outside a predefined range may mean the difference between effective and ineffective procedures - or between saleable and unsellable products.

Types

Many types of data loggers exist to suit various applications, with sizes, speeds, and memory capacities that range widely depending on their use. Recording can be performed manually or through a cloud download process - some even allow real-time access!

Some are designed to operate as stand-alone devices, while others remain attached to a connected computer. Most use a USB or an RS-232 port for communication; some also include 12 V terminals for powering sensors or peripherals.

Analog and digital inputs are commonly found on data logging devices, and their input type must match up with any sensors you require for measurement. Differential inputs may be necessary when measuring temperature or humidity - however, this could reduce available analog inputs by half.

Sample rates and battery life must also be considered when selecting a data logger. Loggers with lower sample rates will allow longer data retention; however, the information may need to be more precise than larger DAQ systems with higher sample rates.

Efficient monitoring is crucial to any business, regardless of industry. Warehouses and storage facilities, for example, should regularly check temperatures, humidity, and light levels to protect stock against damage while keeping within acceptable tolerance levels.

Companies often rely on data logging to keep an accurate record of equipment and machinery, enabling them to operate more efficiently while minimizing downtime. For instance, in factories or workshops, this could include monitoring temperature, pressure, vibration, and flow rates - any deviations will set off an alarm, alarming staff to take appropriate action immediately.

Museums and galleries use data loggers to track environmental conditions within their collections and exhibits, helping ensure they remain safe for future generations. Laboratory environments may also benefit from monitoring temperature and humidity to store samples appropriately.

Applications

Data logging is an incredibly versatile technology with various devices designed to fit a range of uses. They come in all shapes and sizes with various sensors, inputs, and computing and processing power capabilities.

One of the primary uses for devices that record data is monitoring IT infrastructures like web servers or applications, tracking key metrics like uptime and response times to identify any problems as soon as they arise or any metrics that fall outside their expected range - like when an app becomes slow or unavailable.

Data loggers can also be used to monitor the temperature and other environmental conditions of sensitive materials like medicines, electronics, or food items stored in hospitals, labs, or warehouses - particularly if temperature or humidity can impact quality control issues of products being stored there.

A data logger can prevent costly damage, decrease downtime due to outages, and ensure any medical or food products meet regulatory standards. EU rules have very stringent storage and transportation guidelines; continuous monitoring must therefore take place to ensure compliance.

Data loggers can also be used to monitor the condition of structures like tunnels, dams, and high-rise buildings. This allows engineers to detect structural faults or deterioration over time to make repairs before any accidents occur. Likewise, sensors can be set to alarm at predetermined levels should any structure reach an unsafe threshold level, and an alarm signal can be sent if any concerns require immediate action.

Data loggers are now available and are often linked to the internet for instantaneous access to recorded information, providing businesses with a convenient means of tracking machinery, equipment, and other assets remotely, eliminating costly manual inspections. They're also valuable tools in fighting theft; when configured for this purpose, they can send alerts about stolen vehicles or trailers.